ProVector excels at scalability and portability, however it is still,

unfortunately, inferior to Freehand or Illustrator on the Mac or CorelDRAW!

on the PC.

ProVector excels at scalability and portability, however it is still,

unfortunately, inferior to Freehand or Illustrator on the Mac or CorelDRAW!

on the PC.

In the Custom Graphics world, imprintable items like coffee mugs, athletic jerseys, signs, glass trophies, plaques, and t-shirts come alive with computer artwork. There are dozens of material-types and machines necessary to create these customized goods, but you probably already have the most important part of the equation--your Amiga.

Many people do professional Custom Graphics and make great livings, but the Amiga gives you the opportunity to customize for fun. This is where we will start. After all, if it isn't fun, why do it?

Firstly, let's define Custom Graphics. Custom Graphics is the practice of putting graphics-on-demand onto imprintable goods. These goods can vary from glass windows to mousepads to bumper-stickers. Many of these items can be customized in your home, while others require special machinery to mold the graphics media (the material that carries the graphic image before putting it onto the item being customized).

We'll start with the least costly, and easiest projects, all of which have three main steps:

1. Design -- Using Amiga programs to create the graphics.

2. Output -- Using output devices connected to the Amiga to mold the graphics media.

3. Production -- Applying the graphics media to the item being customized, frequently called a "substrate."

We'll concentrate on steps 1 and 2, since they deal with the Amiga; I'll provide links to details on production, located at various web sites, including my own. We'll cover the software you'll need, the output devices which work best with the Amiga, and their related media.

There are a few limitations to this type of transfer. The graphic will not look very nice on dark-colored fabrics, since all printers capable of printing t-shirt transfers use translucent inks. Also, the graphic can fade after a couple-dozen washings.

What's great about these transfers is that they are very cheap to create. One could do a color t-shirt for about four US dollars, including the cost of the shirt. If you sell shirts with custom-made transfers, there is a very high profit-potential.

The first thing to consider when working on t-shirt transfers is the software you are going to use to design the graphics. Does the design program allow you to print in color? Can you create high-resolution images, or will you be limited to what you can see on the screen?

The most-frequently used application for designing Custom Graphics is a structured drawing program, such as the out-of-print Professional Draw or ProVector. I recommend ProVector because it offers pro-quality output and flexibility. ProVector is available from Stylus, Inc. Don't bother using DesignWorks 2.0, because it doesn't offer a large range of colors or good output quality. (Click here for a full review of DesignWorks 2.0.

ProVector allows you to create page layouts using polygons and curves. There are a number of interesting effects that can be enacted on these shapes to make your designs more interesting. In addition, you can include text using PostScript fonts (3 included) and import bitmaps (Amiga-IFF) into the layout. ProVector's graphics engine will allow to do all types of Custom Graphics design, not just t-shirt transfers.

ProVector excels at scalability and portability, however it is still,

unfortunately, inferior to Freehand or Illustrator on the Mac or CorelDRAW!

on the PC.

ProVector excels at scalability and portability, however it is still,

unfortunately, inferior to Freehand or Illustrator on the Mac or CorelDRAW!

on the PC.

A ProVector drawing was used to create the "CUSTOM GRAPHICS" banner at the upper-left of this web-page.

The structured-drawing program should be considered to be the primary design tool in the Custom Graphics suite. ProVector fills the structured-drawing blank well because it supports many kinds of output devices. I recommend running ProVector on Amigas with 68030 or better with FPU.

The next important tool is a bitmap image-processing program, such as StylusTracer (packaged with ProVector), Image Engineer (shareware; see Aminet), or PhotoGenics (from Almathera ). Each program has strengths and weaknesses, however, for t-shirt transfers, they will all work just fine doing color-correction. Color-correction is the most important function of graphics-software when doing wax-transfers. When outputting and producing t-shirt transfers, color-representations are inaccurate. This means that the color you choose to use on the Amiga's screen may not exactly match the one that appears on paper. Even worse, the colors may appear even more differently when the wax transfer media has been heated onto the substrate.

Colors almost always appear darker on paper, and darker still on the substrate. Therefore, be sure to get an image-processing program which allows you to boost the overall brightness of a bitmap. In other words, colors should appear lighter than normal on the screen--and brightness control allows you to make this happen. All of the packages mentioned above will allow you to adjust the brightness of an image.

In addition, many image-processing programs also allow you to smooth pixellated images, perform special-effects such as embossing and refraction, and adjust the color-curves of the image's palette. This allows you to create interesting effects on otherwise dull images. Remember, however, that when creating wax transfers, the images need to be bright.

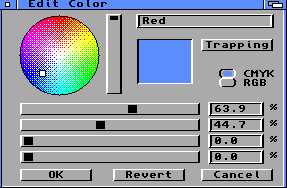

If you are doing all of your design work in ProVector, which does not have

color correction, simply use lighter colors. As seen in the image at left,

ProVector allows you to adjust the CMYK values of each color in its palette

in order to achieve the brightness that you need. Special color palettes can

be saved on disk, so if you create a palette that works particularily well

for t-shirt transfers, you could keep it handy.

If you are doing all of your design work in ProVector, which does not have

color correction, simply use lighter colors. As seen in the image at left,

ProVector allows you to adjust the CMYK values of each color in its palette

in order to achieve the brightness that you need. Special color palettes can

be saved on disk, so if you create a palette that works particularily well

for t-shirt transfers, you could keep it handy.

ProVector also allows you to adjust colors using their RGB (additive) values. You'll find it easier to match colors on screen with real samples once you get used to the color-change that happens when you print transfers.

Thermal printers are more costly, but provide more accurate color-representations and better quality images at 300 DPI. Seiko's ColorPoint series will work with the Amiga's PostScript printer driver or ProVector's built-in PostScript export-module. These printers range from $2000 to $8000, depending on the capabilities.

A less-expensive thermal printer is the Fargo Primera series. This printer offers 300 DPI printing at slightly lower quality than the Seiko, but offers photo-realistic (or dye-sublimation) printing. Bitmaps look fantastically non-pixellated using this method, which migrates the printing inks at high temperatures during the printing process. Currently, however, there is no way to do wax transfers in photo-realistic mode. These printers, which use proprietary Amiga Preferences drivers, range in price from $600 to $1500.

Color ink-jets represent the least expensive solution for printing t-shirt transfers. Canon's BJC-210, a 300 DPI printer, offers entry-level printing for around $150. Wax transfer paper is available from Canon.

If you want to do transfers professionally, go with the Fargo or Seiko printers. If you need to print a lot of transfers quickly, the Seiko is the only choice, because of its speed.

Most thermal wax transfers can be applied with an regular household iron, but this might require a great deal of dexterity on the part of the person applying the transfer. This is because the transfers cool so quickly that the wax may not separate from the paper. So while one part of the transfer is being ironed-on, the rest of the transfer is cooling, making the wax stick to the paper.

The solution for this problem is a heat press. The solution for this problem is a "heat press," available from the world's best maker of said devices (bar-none!), Stahls'.

For more information on transfer equipment and supplies , contact the GamaSoft Custom Graphics Connection for Amiga Users. In the future, we'll cover creating more types of transfers, cutting vinyl for signs and decals, creating artwork for large-quantity jobs, and the best Amiga products for each job. -TW

Written By: Ted Wallingford e-mail: UNKNOWN!! Please TED Send it!!